New reviews by Edward Sison Carbonfan Wheels

I just received my new wheelset from Carbonfan.com. I am participating in their customer review plan and received a discount on the wheelset. That being said I’ll do my best to provide as honest and impartial review. Check out the pictures below and the Youtube video I made here. This review is just for unboxing and setting up the wheelset. Ride review to come at a later date.

Wheelset Details:

29″ Carbonfan XY Asymmetric Rims – 29mm internal/35mm external width, 28H

DT Swiss 350 Boost, straight pull, centerlock

Sapim CX Ray and black aluminum nipples

Weight: 676g (F) + 782g (R) = 1458g (without tape/valves)

Got a excited video from customer in Belgium.

High level carbon rims technologies

Something you should know before you buy carbon road bike wheels

Tax department officer visit ours office.

How we make the carbon wheels

We produce carbon fiber rims and wheels in an impressive way. The process is like a exciting trip, including preparing the basic materials, shaping,building, checking everything and finishing. We will work hard to make sure that the carbon wheelset our guests receive will be satisfactory and meet their needs.

1 The cutting and process of getting the carbon material ready for use

Most of the rim structure is made of Toray T700 full carbon fiber which is efficient and can last for a long time.we use special basalt carbon on the top layer of the brake. This material will make the performance of the brake much more better and you can use the brake for a longer time even though you brakes in an unusual way . We use different densities of carbon fiber on every rim so that it can own a structure which last for a long time. And each carbon fiber piece is cut accurately so that it can meet the carbon rims’ requirements.

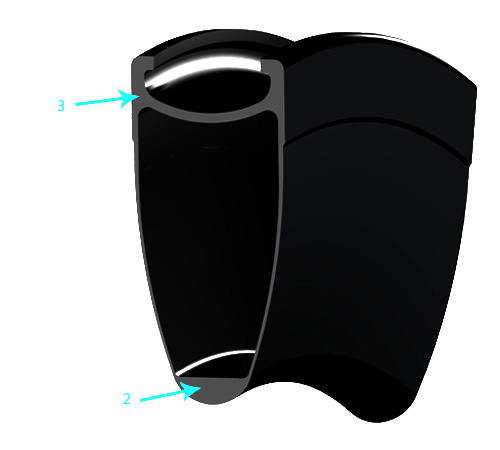

2 The way how to add the carbon fiber into the mould

Every Carbonfan rim is made up of some different carbon layers which are covered with different angles and patterns. And then the unit will become nice and can return to its original shape after being stretched. This special and unusual design makes up a main pattern and the pattern will make the carbon rims strong and last for a long time.

3 how to Layup Molding

Firstly, we will put the braking surface,which is made of basalt, and surface layer of carbon rim into the mould. Secondly, we will put layup into the mold until it is full. In usual cases, it will be processed at high temperature for 45 minutes to make the layup become a carbon rim which is very strong and cannot easily be destroyed.

4 Looking closely at the roundness and weight of every carbon rim

The producing procedures is very important,but at Carbonfan we think checking every rim carefully is also very necessary and important so that our products will be excellent and of good quality. After the rim is removed from the mould, we will check the roundness, lateral measurements, and weight carefully to ensure every unit is

5 Spoke hole drilling

The next step we will make everything based on the customer’s requirements. We will make sure that the position and angle of the spoke holes are absolutely precise and accurate through drilling machine until our customers are satisfied.

6 Clean the carbon rim

During the process of mould, it is very normal to have some flaws,faults and burring. Once we find them, we will clean and remove them from the rims. It will take a lot of time to do the cleaning to make the rims smooth because we pay attention to every detail to make sure that the wheels our customers get are very perfect and beautiful.

7 Putting the last covering of paint onto the surface

When the carbom rims are smooth enough, we will cover the out layer fiber of the rims with thick paint. The paint will not only make them look shiny, but also protect against rocks, chips and unpleasant weather.

8 Wheels Building and Testing

The last step of our producing process is to build the wheels. We put the spokes into the rim and adjust the tension to enough levels. We fix every spoke one-by-one and make it tight to the right torque. Then we do many tests on carbon bicycle wheels including spoke hole tension test, braking surface test and lateral torsion test to make the braking performance better than before and make sure that they are strong and safe enough when our customers are riding bicycles.

Why we deal with several different series of rims?

The riders come to ours Carbonfan store for the first time, they might feel a little confused as they find one series has more or less difference with others.

We have numbers of Series wheels, some of them even have a similar size of rims. so the people don’t know which one they should choose.

To answer this question, We need to explain more about carbon rims.

The carbon rims are typically hand-made products, which means different machine models, tech workers, may deliver a slightly different kind of product. The different character and experience of each leader of the production line can turn out different characteristics of the rims, and then, of the wheels. For most cases, it’s not quite about quality difference, but different features.

But when you ride on the wheels after hundreds of kilometers, you may tell the difference.

Just like a beer of the same brand but made in different cities, it often offers some different tastes to some extent.

XY Series

XY carbon rims series is a very special series because all the designs of the rims are asymmetrical. XY series is good at asymmetric mountain bike wheels. Of course, it owns two types of road bike wheels whose design is also asymmetric. If you are very interested in the asymmetric system, XY series will be your best choice. In recent two years, the asymmetric design is becoming more and more popular, so we especially launch a series to produce asymmetric wheels.

BQ Series

BQ Series is our main series in early years. We always use advanced and innovative design in this series in order to seek more performance. The chief mechanic of BQ series is the former chief engineer of the world’s biggest carbon fiber manufacturer. So he has a better understanding and ideas about the carbon fiber wheels. You will find that the designs of BQ series are more sleek, which will make them have the better intensity and weigh ratio. But it requires strict production ability for the engineer.

TD series

The design for wheels in TD series is classic symmetry. It is still the most commonly used design in the market. If you observe its cross-section carefully, you will find that it is more close to the traditional design for the aluminum wheels. If it is your first time to use carbon fibre wheels, TD will be your best choice. Because they will give you similar felling when you are using aluminum wheels. TD series targets players who use carbon fibre wheels the first time.

YH series

HY series owns the most sizes and attributes no matter mountain bike or road one. What’s more, it provides many “downhill” options in mountain bike. The design for carbon fibre wheels is very mature. If you are a veteran carbon fibre wheels user, you will like that.

CARBONFAN is now proud to present a new type of rim appearance to the riders. first time in the world!

We all know that the present market of carbon fiber bicycles include the appearance of the rim as followed, weave UD, 3K, 12K, 24K, and matte and glossy as finishing surface. In order to prevent visual fatigue, our Ben–series of wheels launch a new look for the rim market. Attached a picture.

As you see, first of all, the brake side on this pic is made from a type of new slip-preventing material chemical. The look of cow-skin, we just call the Cow-stripe braking track temporarily. Compared to the traditional basalt brake side, the touch-braking effect shows up very prominent when riding, which results a obviously higher sensitivity for braking. Thus, the traditional brake side needs a rather long braking times (especially during the downhill process). This avoids the obvious and instantaneous temperature increase of the brake side of the large, greatly reducing the chance of deformation of the brake track. Of course, the special look of the stripe on brakes edge is also much nicer than ordinary basalt brakes, last but not least, CARBONFAN Team think so.

Secondly, the rest of the rim surface (part of the brake track side), we launched the Silk-looking weave in matte finishing. Seeing the picture, unlike the traditional UD matte design without any line nor block on, this new idea of appearance we used in the production process, permits the rims looking and feeling like a real silk, natural, delicate, presenting. The use of breathable weave, helps a lot to achieve such a nice sensory effect, objectively .

Now, as first stage, only three specifications with this SILK appearance of the rim were just introduced to the riders by CARBONFAN, as followed :

1. 30mm depth – Clincher – 23mm width, 410 +/- 10g, SILK-UD-Matte,

2. 38mm depth – Clincher – 23mm width, 440 +/- 10g, SILK-UD-Matte,

3. 50mm depth – Clincher – 23mm width, 480 +/- 10g, SILK-UD-Matte.

Buy wheels from here:

2017 new release 700C width 23mm Clincher carbon road rims BQ series

Only Buy rims form here :

2017 new release 700C width 23mm Clincher carbon road rims BQ series

CARBONFAN suggests it!

Carbon rim Price changed

We noticed some advises from forums , and had a inner meeting with ours boss. completely reviewed ours price. and finally ,We made some important changes:

1 We removed some price increase options, now I m sure you can get it with the price what you are looking at.

2 We reduced the base price after compared with some others store, I m pretty sure we are the one of most affordable rim&wheels manufacturer now!

We are looking into became a leading affordable rims supplier in the world, We have XY XC BQ TD, producing lines offer hundreds chooses of rims.

wish everyone has a wonderful riding time,