High level carbon rims technologies

By info@carbonfan.com | | Comments 0 Comment

1 The material is all made by carbon

We use Toray T700 Material which is full of carbon fiber,The rims will last for a long time and their weight will be very light.

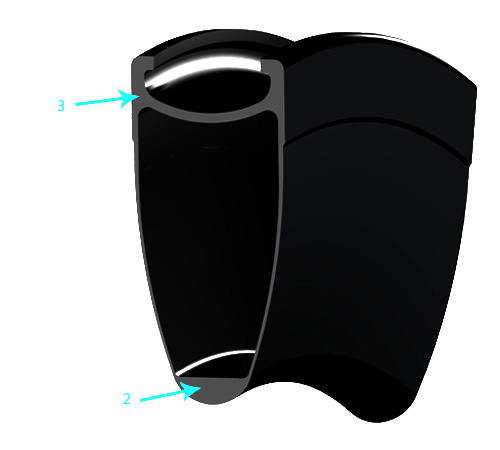

2 The surface of brake is made of basalt

We put stronger basalt on the surface of the brake so that the brake can perform very well and powerfully.

3 The construction is made by hands

The carbon layers are very modern and built by hands. It provides the best and ideal balance of strength and weight.

4 High TG epoxy resin,which is a strong glue

We put stronger high TG resin fiber on the surface of the brake so that the brake can perform very well and powerfully.

5 Additional High Mould Carbon Strip

The spoke holes are very rigid and difficult to move.

It makes our customer able to use them for a long time and improve the tension of spoke hole

6 Design with wide aerodynamics

The profile consists of 25 wide and mordern aerodynamic rims. It can make drivers control cars more easily and reduce the resistence when the wheels are rolling.

7 Engineer's design for the outline of rims

The feature of the rim is its hardness. If you want to climb with your bikes, make your bikes faster or follow others, you will be very satisfied with them because we have made the performance better than before.

8 MTB DESIGN with less hook

This design will make the performance of traction better and you can steer the car easier when going around corners.

It is hard and rigid. And we improve impact resistance greatly.

The design of carbon clincher rims

1.Our material consists of 23 layers carbon which make sure the weight of the carbon clincher rims is very light. This is our advantage to compete with competitors. At the same time, we use durable and reliable braing to keep safety.

2.There are 9 layers in the side wall of the rims with a combination of different angles of carbon fiber materials. That makes the rims able to resist high force coming from different sections.

3. Up to 36 layers of carbon rims are used in the important spoke hole bed to make sure that the carbon rim will make the cycling stronger and durable when the riders run into different road conditions.

The design of features

1. The channel of tire

We use the carbon fiber with high angle(90 degree) in order to increase tire pressure as much as possible on the design of tire channel. It can reach up to 169 psi without any extra risks and damages according to the performance data.

During the process of production, the tire channel will experience additional testing because it is very important when we combine the carbon clincher rims together.

2 Stronger strip made of high mould carbon fiber

We add high mould carbon fiber reinforcement strip into the inside part of the rim in order to give additional protection to avoid breaking through the spokes and having a small hole in the tire that is caused by a sharp point.

3 Design in three dimensions

One direction(0 degree) carbon fiber is used on the 3D section so that it will make rims continuous and improve its firmness.

The cross line structure formed by two kinds of designs. One is the high degree carbon tire channel, the other is the low degree 3D section carbon. It provides a connection between the tire channel and rim side wall. At the same time, it improves durability and strength of the whole rim.