Nowadays,there are many different types of riding a bike,and riding a bike on road is one of the most popular ways. Many people would like to go out riding with others and have a race which are not particularly for professionals. Speed and distance have a great effect on these riders. The difference between leading the group and riding at the last is very small.

1.There are two ways to make your cycling skills much more better than before. One is to train yourself hard so that you can ride a bicycle for longer periods of time. The other is to improve your bike which can has a more powerful and efficient performance. You should try to enjoy the race in a freind way.

That's why carbon wheels exists. They are lighter and have better aerodynamics than standard metal wheels. That means riders who ride a bike with carbon wheels will be easy to ride faster than those whose wheels are not made of carbon.

If you replace your current wheels with carbon ones, you will become a better and faster cyclist right away. There is no other better way than using a aerodynamic carbon wheels.

If you want to upgrade your bike, changing to road bike with carbon wheels will be the most valuable. They are a little expensive,but they will pay off when you compare the prcie with the improvement on the speed.

2.The difference between"Clincher Wheels" and " Tubular Wheels"

Here is the answer: if you want to take part in a competition, you can choose tubular wheels. If you are looking for all-around wheels, you can choose clincher wheels. There are more criteria other than the two mentioned,but most people will buy a bike according to that two criteria.

Clincher and Tubular mean the type of rim and which type of tire can be used on the wheel.

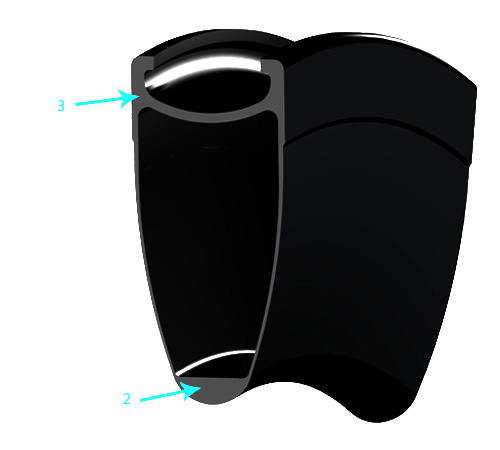

Carbon clincher wheels are the most common type and can be used with a tire and inner tube. If your have a flat clincher wheel, you can change the inner tube and go on cycling quickly.

The weight of carbon tubular wheels are lighter and its price is cheaper, but you have to use specific tubular tires. Firstly ,you should put the tires and inner tube together to become one piece, and then we will use glue to stick it to the wheel. In most cases, tubular tires are more expensive than clincher tires. If you are in a flat road, they are not very easy to be changed.

If you want to change a tubular tire, you will have to remove the glue from the tire and stick fresh glue to the new tubular tire. It will take some time to wait the glue dry. Many people will not be glad to change it when they are going cycling. The reason why tubular tire is popular with professional racers is that it is cheaper and lighter but not convenient.

Why do some famous corporations only produce tubular carbon wheels? The reason is that nowadays it is very difficult to produce a carbon clincher wheel which can be strong enough in our daily life.This is why some corporations only sell tubular wheels and use aluminum rims to glue onto aerodynamic carbon fairings.

at carbonfan We have advanced technology in making clincher wheels. We use a special type of material on the rims which is called basalt. Basalt makes the carbon clincher wheels very strong and durable when you are go cycling. The weight is very light and the performance is very good.

3 Is it a truth that wider rims are better?

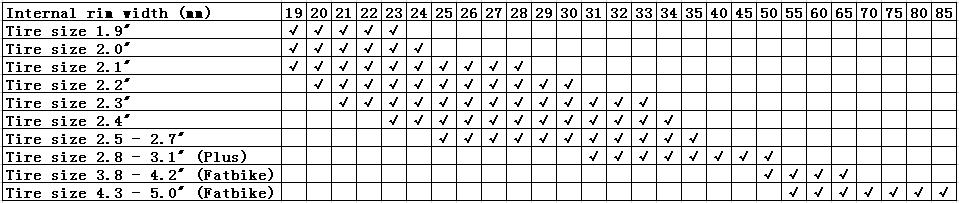

The width of the rims is usually 19mm for most carbon road bike wheels. But recently the improvements on the wheels have shown that wider wheels are better.

Why is wider rim better? There are 3 reasons including aerodynamics, handling, and rolling resistance.

1. A wider rim is more aerodynamic. The wider the rims is , the better will it match the width of the tire. This creates a balance of pressure from the front wheel to the back wheel, which results in a smoother flow of air on the wheels and bike. That is to say, you can ride a bike faster and more efficiently.

2. Wide rims make you have a better handling. In the case of clincher wheels, a wider rim spreads out the sides of the tire in round shape, which improves the handling by strengthening the consistency of the tire shape throughout different types of turns, especially some hard turns. In case of tubular wheels, the shape of the tires is always round, which is decided by the production of tubular tires. A wider rim increases the connection between the rim and the tubular tire while reducing the possibilities of tire rolling sideways off the rim. And this makes the wheel safer and you can steer the bike better when you are making a hard turn.

3. Wide rims can reduce the rolling resistance. In the case of clincher wheels, the wider rim allows the tire to spread out wider, which changes the shape of tire’s contact patch and some parts that contact the road. If you use a narrow rim, the contact patch will be in a rectangle shape. If you use a wider rim, the contact patch will be wider. And it will be in a square shape, which will reduce the rolling resistance of the tire and improve the speed and efficiency.

Are wheels with wider rims heavier and will make the speed slower? A wheel with wide rim will be heavier because it is made up of more carbon fiber. Generally, most people think that the cycling speed will be slower if you use a heavier wheel. In fact, it is not true because the advantages of aerodynamics, handling, and rolling resistance outweigh the added weight. If you want to compare the specifications of different wheels, that is the key point. If you use a wide rim wheel instead of a narrow one, you can ride faster even though the weight reaches to hundreds of grams.

How to define the width? The standard width for a road bike rim is 19mm. If the width is more than 23mm, it can be defined as “wide”. Carbonfan defines the width as 25mm, which means the width of brake surface is 25mm in order to form compatibility with brakes and frames.

So if you ask me whether wide rims are better, I will answer you “YES” with certainty.

4. What does 38 , 50, 60, 88 mean?

You have learned how to choose the wheels between clincher and tubular ones in last lesson. Now i will tell you the meaning of these strange numbers:38,50,60,80.

These numbers represents the depth of the wheel's aerodynamic rim. Their unit is millimeter. I will take 38mm for example. This means the rims extends an extra 38mm towards the center from where the tire meets the wheel. 88mm means the rim extends 88mm from the tire.

Why is it very important? One of the biggest advantages of carbon raod bike wheels is the aerodynamics. They will decide how fast and efficiently a cyclist can ride. When you are going cycling with your friends, and leave behind others, it will be easier for you to keep up with them because of the great aerodynamics.

The biggest source of slow aerodynamic turbulence is the rolling wheels. We really value that problem so we built the wheels which have the advantage of aerodynamics. We also increase the depth of the rim. The deeper the rim is, the more aerodynamic the wheel will be, and you will go riding faster and efficiently when you go through the wind as well. Rim with the depth of 88mm is more aerodynamic than that of 38mm, which will make your speed faster when you are in the situation of important aerodynamics like triathlon.

Since rims with 88mm depth are more aerodynamic, why will people choose rims with 38mm? If a wheel becomes aerodynamic, it can be easily affected by cross wind or lateral wind. Let’s image that when you use the front and rear rim with 88mm depth, your riding speed will be very fast because of the aerodynamics of deep wheels. But if the wind comes from the side direction, it will blow the large rims and the whole bike to other directions. It will not matter a lot if you ride a bike alone like triathlon, but if you ride a bike with many other cyclists, you will hit others unless you pay closely attention to your riding.

Is there any solution to this situation? There will have less effect but less aerodynamic advantage if you choose the rim with shallower depth. if that doesn’t work out ,you may consider factor of weight. Wheels with 38mm depth will lighter than that with 88mm depth because less carbon is applied to them. If you ride a bike with a lighter wheel, your riding speed will be improved. At the same time, it will make you easier to ride up the hills. So if you like climbing hills and sprint, rims with 38mm depth will be your best choice.

Why do you often see a bike with different front and rear wheels? Because the front wheel is used to steer the bike, which is easily be affected by the cross wind. Rear wheel will not be affected largely because it is fixed in a straight line with the bike. You can choose a rear wheel with deeper rim for not affecting the handling. carbonfan offers wheelsets with 38mm-50mm to solve this problem. This kind of wheelset is made up of a front rim with 38mm depth and a rear rim with 50mm depth. Now you can take advantage of aerodynamics to keep your bike stable enough even in windy conditions.

Do you know how to choose wheels? I think it is one of the hardest things for cyclists to choose a suitable wheels. Firstly, you should think about the situations when you are riding. You can choose a wheelset with 38mm depth if you often go cycling along the mountain. You can choose a wheelset with 50mm depth if you are an all-around cyclist. If you are an all round cyclist who seek for more aerodynamic advantage, you can choose a wheelset with 60mm depth. If you like go cycling alone or take part in the triathlon, you can choose a wheelset with 88mm depth.

It is still difficult for you to decide on which one to buy? You can just choose a wheelset with 60mm depth because it is the most popular and great one which owns all around wheelset. But if you join in a triathlon, just choose the one with 60-88mm depth for its popularity among the triathlon athletes.

5. Are Spokes and Hubs important? The answer is yes.

What’s the difference among different spokes? Carbonfan provides all kinds of spokes. The standard spokes are pillar ones. We also upgrade to the spoke Sapim CX-Ray, which are the best ones in the world. They are much more stronger, lighter and aerodynamic.

Which kind of riders need to upgrade the spokes to Sapim CX-Ray?

If you are a strong and fat rider, the increased strength of the Sapim spokes will keep your wheel longer. At the same time , if you want your wheels to perform best, the increased aerodynamics and lightweight will give you a wheelset with excellent performance.

In fact, the standard pillar spokes are also very good. We are glad to recommend them to people who want a great wheelset which will cost them a fortune. If you can’t decide which one to buy, just choose the standard spokes because it is much cheaper. If you have a good understanding of the good performance of Sapim CX-Rays, don’t hesitate to upgrade it.

How do choose good hubs? Carbonfan mainly offers 3 different road bike hub sets. Our standard hubs are

DT Swiss 350. We also provide

DT Swiss 240s , which are upgraded based on DT Swiss 350 . And we also have especially upgraded

Hope Rs4 hub sets.

The standard DT Swiss 350 hub is pretty good, and it is also our most popular hub. We will recommend it to riders who want a great hub set at a reasonable price.

The DT Swiss 240s hub is lightweight. It is more durable and will roll faster. You don’t need to check and repair all the time.

The DT Swiss 240s and Hope RS4 hub set is marvelous, but to be honest, you will have to pay much more money for it due to the factor of brand effect. If you want to get your friend's approval, just choose DT Swiss 240s or Hope RS4 hub set.

If it is hard for you do decide which one to purchase, I will recommend the standard spoke, the standard DT Swiss 350 , They are all very great and I'm sure you'll love them.